|

APS has the capability to test pipe joint sizes

from 4" diameter to 60" diameter. The pipe joint testing

will conform to

the requirements of ASTM D3212 or special testing

capabilities are available.

With over 20 years of pipe joint design experience

in the

pipe business APS knows how to design and test pipe

joint. |

|

|

| Testing Equipment

The testing equipment is capable of performing the

pressure and vacuum testing requirements of ASTM D2312. Also the

equipment is capable of performing the misaligned test to the

manufacturer's specification. Lastly the specialized test

equipment is capable of

performing the 5% deflection test requirement. |

|

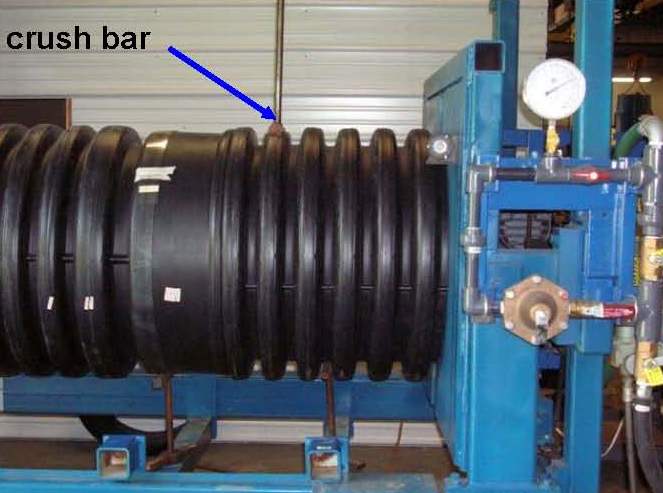

| Deflection Deflection

testing (as shown right) is performed with a crush bar located 1/2 the pipe diameter from the

center line of the gasket or at the end of the bell whichever is

greater.

Deflection testing is designed to simulate rock

impingement near the pipe joint. |

|

|

Angular

Misalignment

Angular misalignment is also tested (as shown

right).

Angular misalignment is designed simulate

deficiencies in contractor installations such as grade or alignment

problems.

|

|

|

|

Certification

3rd party certification is also available. The certification will

be signed by a registered professional engineer, if necessary, to certify

successful completion of the pipe

joint testing. |

|

|

Pipe Joint Design Services APS has developed a pipe joint

design calculator which takes into account the viscoelastic behavior of

the bell, spigot, and gasket material. This design calculator is highly

accurate and is useful in trouble shooting or perfecting pipe joint designs.

APS has teamed up with arguably the premier gasket

supplier in the pipe industry to provide quick design, gasket fabrication and

testing turnaround service at one locations. Follow this link to more

information on the lubeless gasket. |

|